The Essential Role of the Crankshaft of an Engine in Diesel Performance

The crankshaft of an engine is one of the most crucial components in any engine, especially in diesel engines where reliability and performance are paramount. Understanding the function, importance, and maintenance of the crankshaft helps both engine mechanics and vehicle owners maximize efficiency and longevity in their diesel engines. This article delves into the intricacies of the crankshaft, how it operates, and the implications it has on performance and maintenance.

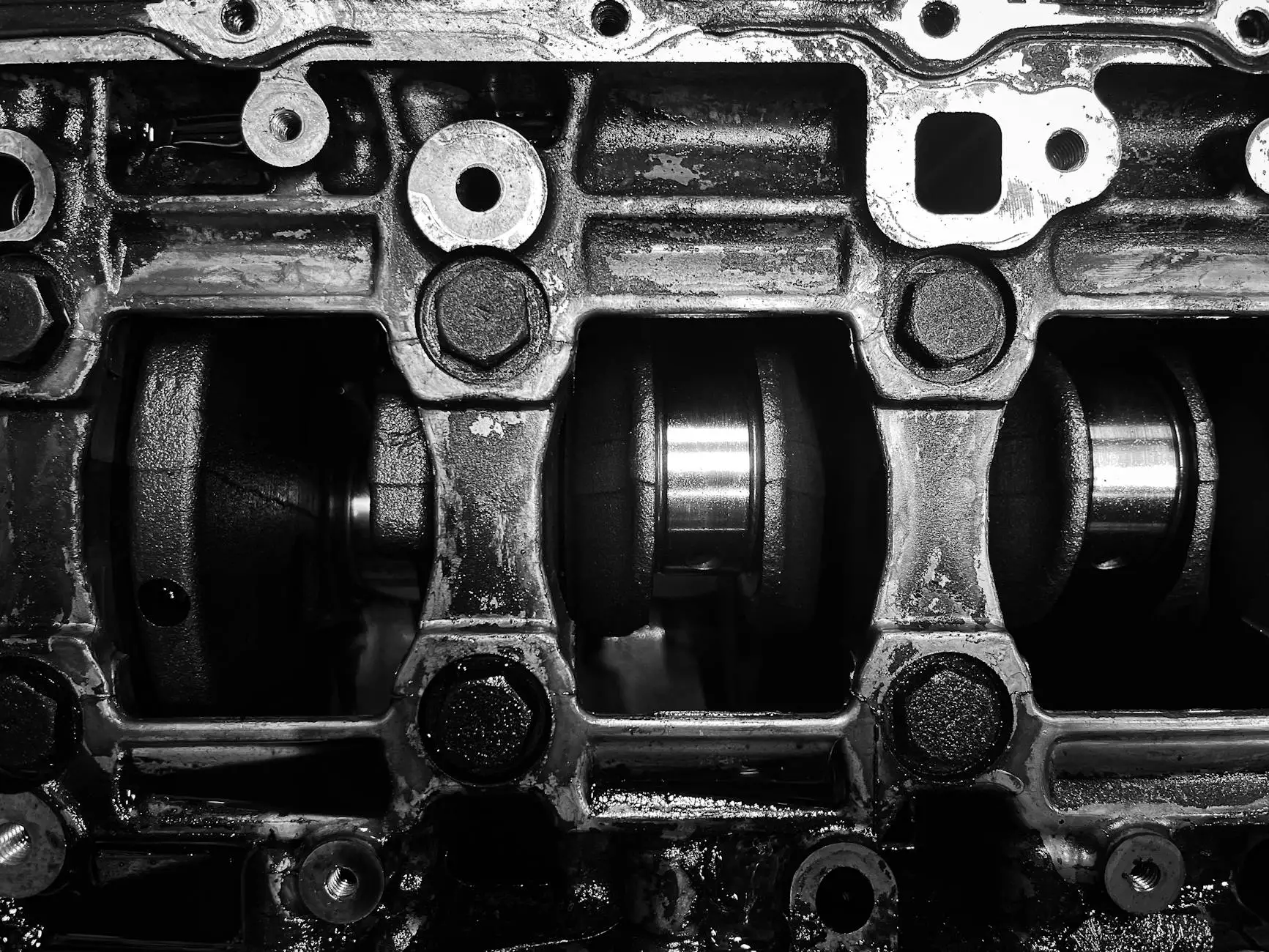

Understanding the Crankshaft: The Heart of the Engine

The crankshaft is often referred to as the heart of the engine. It converts the linear motion of the pistons into rotational motion that ultimately powers the vehicle. This section outlines its fundamental characteristics, structure, and function.

Function of the Crankshaft

The primary role of the crankshaft is to convert the up-and-down motion of the pistons into a rotary motion that can be used by the drivetrain. The crankshaft operates through a process called “crankshaft rotation,” which is crucial for the overall functioning of the engine. Here’s how this function plays out:

- Piston Movement: As the fuel-air mixture ignites, the pistons move downwards.

- Crankshaft Rotation: The movement of the pistons is transmitted to the crankshaft, causing it to rotate.

- Power Transmission: The rotational energy is then transferred to the flywheel and, subsequently, to the drivetrain, propelling the vehicle forward.

Structure of the Crankshaft

A typical crankshaft consists of several critical components:

- Main Journals: The main journals support the crankshaft and allow it to rotate smoothly around the engine block.

- Crankpins: Also known as connecting rod journals, they connect the crankshaft to the pistons via connecting rods.

- Counterweights: These are essential for balancing the crankshaft, minimizing vibrations, and ensuring smoother operation.

- Snout: The front end of the crankshaft that connects to the harmonic balancer and the timing components.

The Importance of the Crankshaft in Diesel Engines

In diesel engines, the crankshaft plays an even more significant role due to the unique characteristics of diesel fuel combustion. Here, we explore why the crankshaft is essential for optimal diesel engine performance.

High Torque and Power Output

Diesel engines are known for their high torque output, which is essential for applications like heavy-duty trucks and machinery. The crankshaft of an engine is designed to handle this high torque and efficiently transmit power. The robust design of diesel crankshafts allows them to endure greater loads without warping or failing.

Durability and Reliability

The reliability of a diesel engine can largely be attributed to its crankshaft. Given the high compression ratios present in diesel engines, crankshafts must be built from high-strength materials to withstand extreme conditions. Regular maintenance and timely replacement of worn crankshafts are essential in diesel engine longevity.

Maintenance of the Crankshaft: Best Practices

To ensure the crankshaft and the entire engine system operate efficiently, it’s crucial to adhere to specific maintenance practices. Here are some tips for maintaining the crankshaft in diesel engines:

Regular Oil Changes

Engine oil lubricates the crankshaft and its associated components. Regular oil changes prevent wear and tear, keeping the crankshaft in optimal condition.

Monitor Engine Intervals

Pay attention to engine noise and performance. Any unusual sounds might indicate potential issues with the crankshaft, such as bearing wear or misalignment.

Proper Engine Load Management

Avoid overloading your diesel engine. Excessive weight can stress the crankshaft, leading to premature failure. Always adhere to the manufacturer's recommended weight limits.

Where to Find Quality Diesel Engine Parts

When it comes to sourcing high-quality diesel engine parts, including the crankshaft of an engine, it's vital to choose reputable suppliers. Here at client-diesel.com, we specialize in providing a comprehensive range of diesel engine parts at competitive prices. Here’s why you should consider sourcing from us:

Wide Range of Spare Parts

Our extensive inventory includes everything from crankshafts to connecting rods, pistons, and gaskets. We ensure that all our parts meet or exceed OEM standards, guaranteeing compatibility and reliability.

Expert Guidance

We offer expert insights into choosing the right parts for your specific diesel engine model. Our team of professionals is well-versed in diesel engine mechanics and can assist you in making informed decisions.

Competitive Pricing

At client-diesel.com, we believe that quality doesn’t have to come at a premium. We offer competitive pricing on all our products, ensuring value for money.

Customer Satisfaction

Our commitment to customer satisfaction is unwavering. We strive to provide excellent service and support throughout your purchasing experience.

Conclusion

The crankshaft of an engine is undoubtedly a vital part of diesel engines where performance, durability, and reliability are concerned. Understanding its mechanics and maintaining its condition is essential for any diesel vehicle operator or mechanic. With proper care and sourcing high-quality parts from trusted suppliers like client-diesel.com, you can ensure that your diesel engine operates at peak performance, delivering the power and reliability you need in every situation.

FAQs about Crankshafts

1. What is the life expectancy of a crankshaft?

The life expectancy of a crankshaft depends on the engine type, maintenance practices, and operating conditions, but they can last for hundreds of thousands of miles with proper care.

2. How can I tell if my crankshaft is damaged?

Signs of crankshaft damage include unusual engine noises, oil leaks, and vibrations during operation. Regular inspections can help identify problems early.

3. Can I replace the crankshaft myself?

Replacing a crankshaft is a complex task that requires advanced mechanical knowledge and specialized tools. It's advisable to have it done by a professional mechanic.

4. What are the common materials used for crankshafts?

Crankshafts are typically made from high-carbon steel or iron, which provides the necessary strength to withstand high forces.

Final Thoughts

With an appreciation of the significant role that the crankshaft of an engine plays in diesel performance, engine owners can take proactive steps to ensure their systems run smoothly and efficiently. Always remember that preventative maintenance and using the right parts are keys to success in the world of diesel engines.